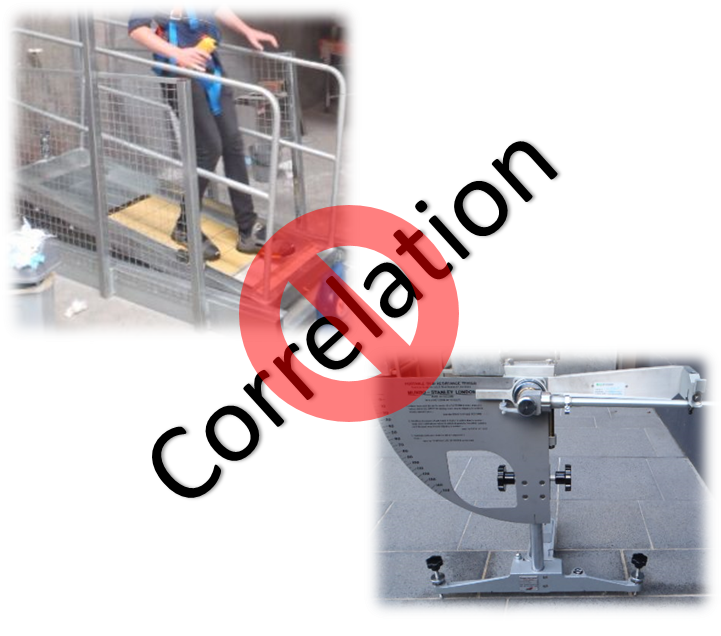

We are often asked to provide a table of the correlation between AS4586 Wet Pendulum results and Oil-Wet Ramp results. In short, there is no correlation. These two test methods vary greatly and the final results do not relate.

Pendulum testing utilises water as the contaminant with a flat piece of rubber used to contact the test surface. The apparatus consists of a swinging arm which is set up with a specific path length for the rubber to maintain contact with the surface. The test results obtained are the BPN, British Pendulum Number, which is averaged to provide the SRV, Slip Resistant Value, which is used to determine the P number classification.

Oil-Wet ramp testing utilises motor oil as the contaminant with the test personnel wearing a specific pair of safety boots to contact the test surface. The test method involves the test personnel walking backwards and forwards on a ramp whilst gradually increasing the incline. The angle at which the test personnel slips, or feels unstable, is recorded and the R number classification is then determined.

These are two drastically different methods which rely upon different testing equipment, different contaminants, different contact materials and different classification criteria. When comparing the results of such different tests there is no correlation.

What does this mean?

If you have one test value, be it a pendulum number or ramp number, you cannot use it to determine what the other value may be. The National Construction Code and Handbook 198 include tables with required and recommended slip resistance ratings for various surfaces. These tables provide both the R rating and P rating for each surface.

Do not get confused, this does not mean that these ratings are equal. What it means is that both of these classifications would be considered sufficient for the surface.

The R rating meets the requirements but P rating does not?

All too often we see products reported to achieve an R10 rating, which is listed in Handbook 198 as suitable for use in internal wet areas, only to achieve a P1 or P2 with pendulum testing. Due to the variations between the test methods you cannot guarantee that the R10 product you selected for an internal wet area will comply when tested in situ with the pendulum.

The only way to ensure a product will comply with the required and recommended P ratings is to have it tested with the pendulum. No one wants to install a product based on the R rating only to discover later on that it is not suitable based on the P rating.

Once the product has been installed you cannot conduct the ramp test again, therefore if onsite pendulum testing produces a result below requirements you will not be able to check if the R rating is sufficient. To prevent this situation obtain the pendulum rating before installation. If you discover that your R10 product is also a P2, you can select another product which meets the minimum P rating and save yourself a lot of time and money.

Author: Amy Morris

Email: Melbourne@FloorSlipTest.com.au

Amy Morris is a Property Risk Assessor at Safe Environments Victoria with a Bachelor of Science (Forensic Science) and associated Biology major and Forensic Chemistry sub-major. Having worked both nationally and internationally in her field Amy is familiar with current standards and legislation for asbestos and other hazardous substances. Trained under Safe Environments NATA endorsed training program she regularly conducts residential and commercial asbestos inspections and provides consulting services to individuals and companies.