Integration Of Slip Resistance Values Within A Risk Management Framework: A Human Gait Based Approach Using Reference Samples

by Carl Strautins and Martin Daniel

Abstract

Many slip resistance testing standards assess the relative safety of flooring materials by specifying a universal minimum threshold expressed as a Slip Resistance Value (SRV); limiting the use within a risk management context. This study contextualises slip related injuries in a simplified risk management strategy to prioritise slip hazards in conjunction with a broad spectrum of health and safety related hazards in an occupational hygiene setting. Four reference surfaces within ASTM F2508 Standard practice for validation and calibration of walkway tribometers using reference surfaces, were tested by five accredited laboratories to AS/NZS 4586:2004 Slip resistance classification of new pedestrian surface materials conducting slip testing with the pendulum friction tester. The results were evaluated and categorised in terms of likelihood to evaluate within a risk assessment matrix along with qualitative descriptors of slipperiness.

Introduction

The Required Friction Demand (RFD) or Ground Reaction Forces (GRF) assessed by subjects walking across force plates has been well documented (Redfern et al, 2001); however there has been relatively little evaluation of the GRFs, risk of slipping and the SRVs obtained by tribometers (Powers et al, 2010). This has led to the development of ASTM F2508 which establishes a validation method to properly rank and differentiate slipperiness of surfaces based on the incidence of slipping during controlled trials of subjects walking over reference samples at a hurried walking pace (approx. 2.1 m/s), to that of the measurements obtained using a tribometer. The purpose of this paper is to validate the results obtained by Powers et al (2010) in context with a published test method and provide an initial framework to apply a systematic risk management process to slip related incidents.

Experimental Method

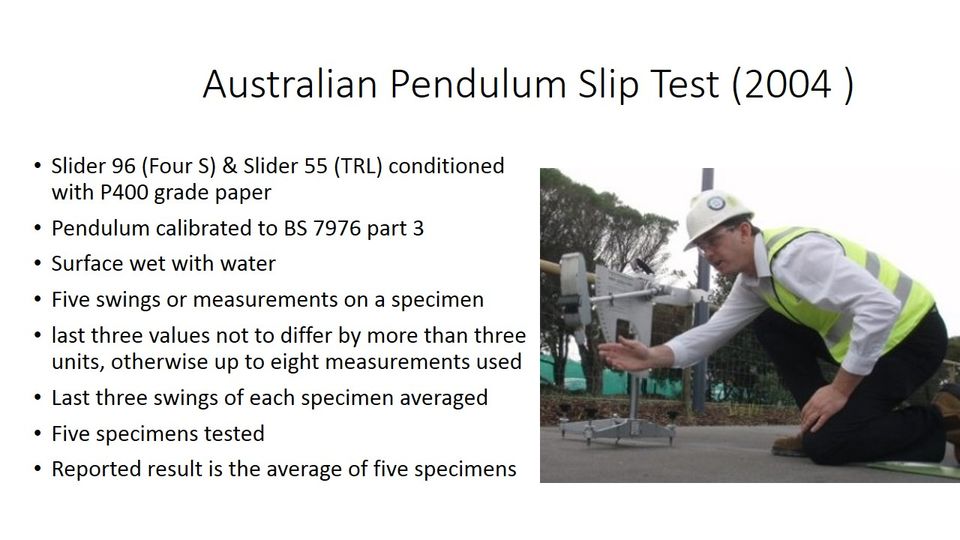

The four reference surfaces as part of ASTM F2508 were tested to AS/NZS 4586:2004 Appendix A Wet Pendulum Test Method using both hardness sliders of 96 (Four S) and 55 (TRL). ASTM 2508 requires testing RS A with a surfactant, however testing was conducted with water for all reference surfaces to maintain consistent test conditions. Each laboratory received five sub divided samples as part of a simultaneous proficiency testing scheme in line with ISO/IEC 17043:2010 Conformity assessment – General requirements for proficiency testing. The laboratories were accredited to ISO 17025:2005 General requirements for the competence of testing and calibration laboratories by the National Association of Testing Authorities (NATA).

Results

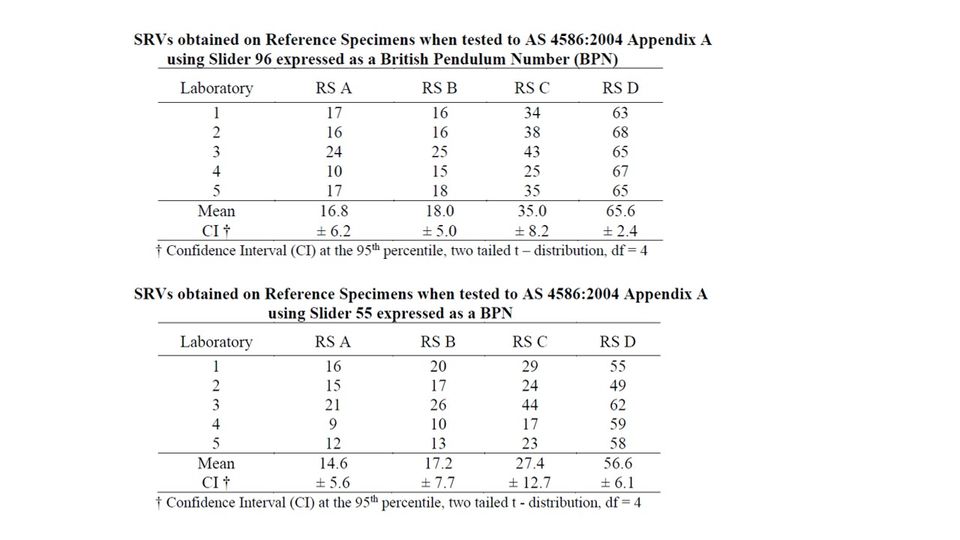

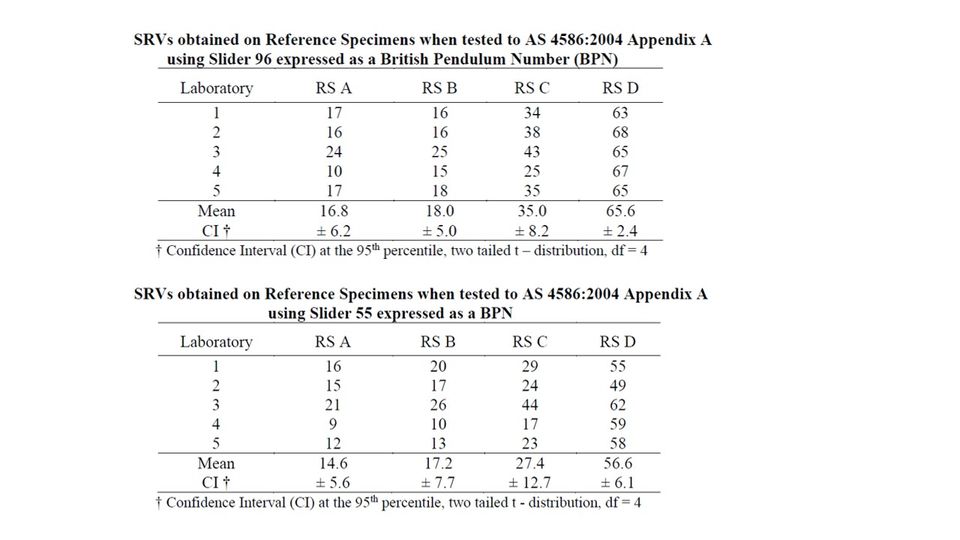

The mean of the inter-laboratory results correctly rank the reference surfaces for both slider 96 and slider 55. There was significant statistical difference (t value > 2.78, paired t test 95th percentile, df = 4) between each adjacent reference surfaces with the exception of RS A / RS B for slider 96. This may be due to two laboratories incorrectly ranking RS A and RS B, slider variability, inter operator error and bias from the calibration facility. For slider 55, all surfaces were ranked correctly and had statistical significance between adjacent ranking surfaces. Slider 55 being more representative to the human gait based trials which is likely influenced by the shoes being Shore A hardness of 70.

Table 1. SRVs obtained on Reference Specimens when tested to AS 4586:2004 Appendix A using Slider 96 expressed as a British Pendulum Number (BPN)

| Laboratory | RS A | RS B | RS C | RS D |

|---|---|---|---|---|

| 1 | 17 | 16 | 34 | 63 |

| 2 | 16 | 16 | 38 | 68 |

| 3 | 24 | 25 | 43 | 65 |

| 4 | 10 | 15 | 25 | 67 |

| 5 | 17 | 18 | 35 | 65 |

| Mean | 16.8 | 18.0 | 35.0 | 65.6 |

| CI † | ± 6.2 | ± 5.0 | ± 8.2 | ± 2.4 |

† Confidence Interval (CI) at the 95th percentile, two tailed t – distribution, df = 4

Table 2. SRVs obtained on Reference Specimens when tested to AS 4586:2004 Appendix A using Slider 55 expressed as a BPN

| Laboratory | RS A | RS B | RS C | RS D |

|---|---|---|---|---|

| 1 | 16 | 20 | 29 | 55 |

| 2 | 15 | 17 | 24 | 49 |

| 3 | 21 | 26 | 44 | 62 |

| 4 | 9 | 10 | 17 | 59 |

| 5 | 12 | 13 | 23 | 58 |

| Mean | 16.9 | 17.2 | 27.4 | 56.6 |

| CI † | ± 5.6 | ± 7.7 | ± 12.7 | ± 6.1 |

† Confidence Interval (CI) at the 95th percentile, two tailed t – distribution, df = 4

Table 3. Calculated t values between reference surfaces (paired t test)

| t value | RS A / RS B | RS B / RS C | RS C / RS D |

|---|---|---|---|

| Slider 96 | 1.18 | 8.72 | 9.51 |

| Slider 55 | 3.20 | 5.01 | 6.97 |

Discussion

The inter-laboratory variability is practically significant when assessing the upper confidence limit for purposes of determining compliance with building codes, workplace health and safety regulations and as evidence relied upon in legal proceedings; the effect being that recommendations for SRVs may be overly conservative to account for inter-laboratory variability which may lead to unnecessary over specification or unjust findings in legal proceedings.

Variability may be reduced through refinement of standardised test procedures, calibration methods or the use of reference samples to normalise results across laboratories, such as the use of the ASTM reference surfaces. The verification of improved testing and calibration methods to reduce variability should be validated through the use of proficiency testing with accreditation to AS/ISO 17025 and ISO/IEC 17043:2010.

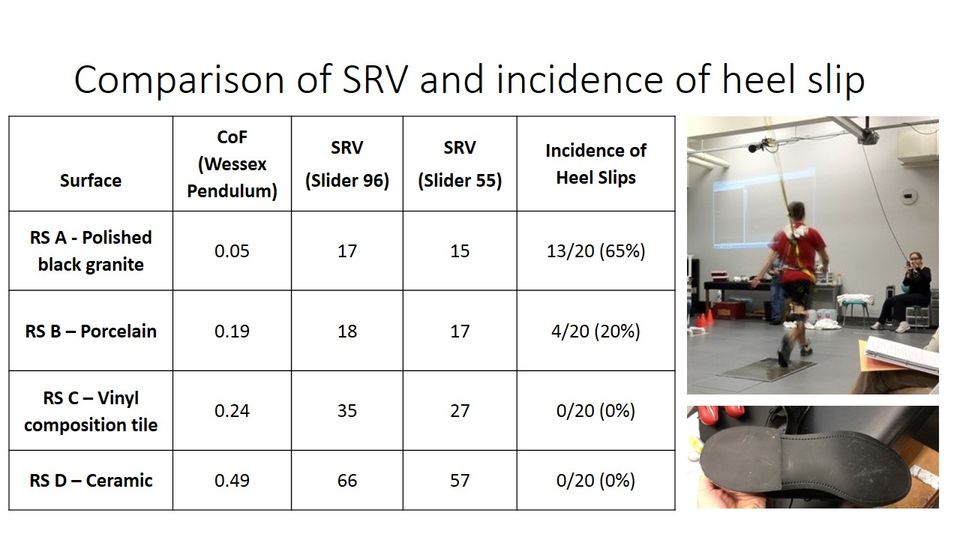

The results reported by Powers et al (2010) for the four ASTM reference surfaces RS A, RS B, RS C & RS D using the Wessex pendulum were CoF of 0.05, 0.19, 0.24 and 0.49. This equates to a BPN of 5, 20, 24 & 46 using the formula provided within Standards Australia HB 197. With the exception of RS B, these results were found to be outside the confidence limits at the 95th percentile when tested to AS 4586:2004. The differences may arise due to the slider batches and conditioning protocol, the number of swings over the specimen to record a result and the calibration methods on the equipment used.

The ASTM 2508 reference surfaces as reported by Powers et al (2010) provide an initial guide as to the risk of slipping at a hurried stride (approx. 2.1 m/s) when unknowingly walking on a surface wet with water, which tends to be between the SRVs of RS B (4/20 heel slips) and RS C (0/ 20 heel slips). This however is not representative of normal walking pace of 1.3 m/s observed by Finnis & Walton (2008), thereby providing a factor of safety.

The incidence of heel slips should be used as the basis of the risk of slipping as falls generally result from the heel slipping during weight transference. Toe slips generally do not lead to a fall; however toe slips can provide important proceciprocal feedback to the individual to indicate that a surface may be ‘detectably slippery’ thereby leading to a reduction in the resultant GRF and a subsequent reduction in the risk of slipping.

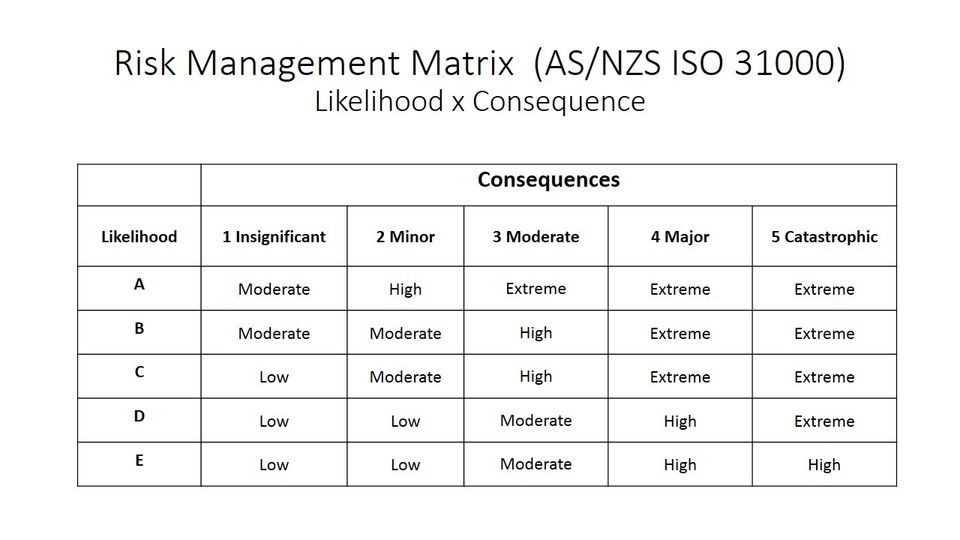

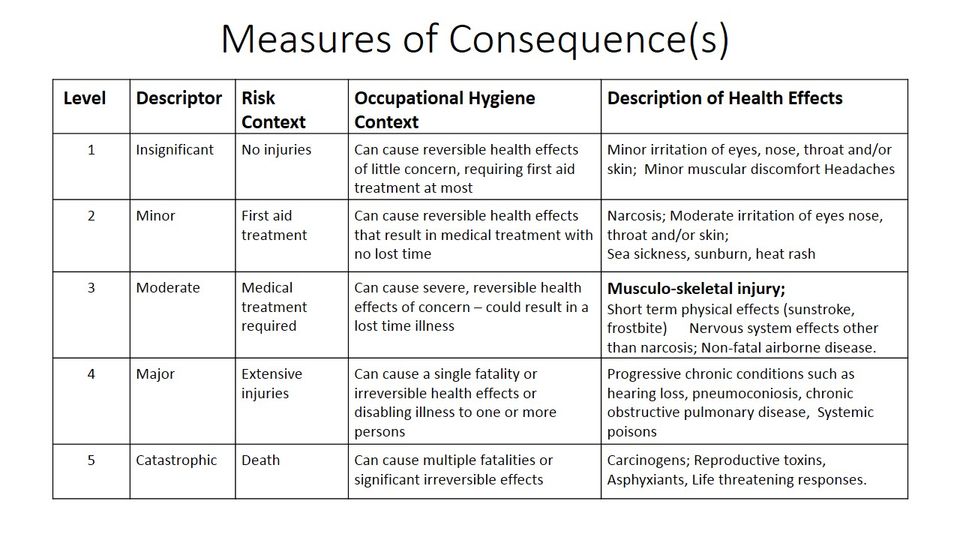

Tables 3, 4, 5 & 6 were modified from a semi-quantitative risk management framework outlined by Firth et al (2006) which is used by the Australian Institute of Occupational Hygienists (AIOH) when assessing a range of physical, chemical, ergonomic and biological hazards. The overall risk is contextualised by providing a semi quantitative analysis by determining the health impact in combination with the likelihood of the health impact occurring.

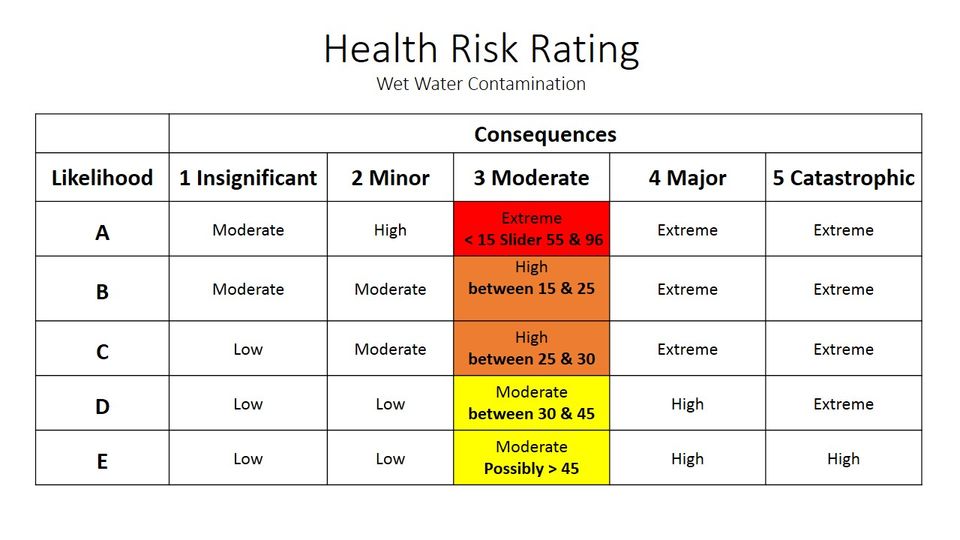

The likelihood or risk of slipping can be evaluated by an assessment of the incidence of heel slips compared with the SRV of reference surfaces. Table 4 provides a summary of the qualitative measure of likelihood based on ASTM 2508, AS/NZS 4586 considering 95th percentile upper confidence limits of the inter-laboratory testing, Firth et al (2006), Standards Australia HB 197, Hunter et al (1985) and Powers et al (2010). The SRV in which a disproportionate number of people are likely to slip when walking at a normal walking pace and unknowingly stepping onto a wet surface, is likely to be that offered by RS B. SRVs greater than RS B form a logical starting point as an ‘unlikely’ event. The SRVs provided are for initial guidance and are based on upper confidence limits to account for inter-laboratory variability, which may reduce when assessing individual tribometers with the ASTM reference surfaces.

It is important to qualify that the measures of likelihood are based on the conditions in which the surface is tested and that of the human gait studies walking on the reference surfaces. In this study, this risk matrix relates to the risk of a person unknowingly walking onto a water wet surface; the risk would be reduced if a person was already walking on a wet surface as they generally should be able to perceive the conditions being wet and potentially slippery and adjust their gait accordingly. Similarly confounding factors such as foot wear, sloping surfaces, contaminants other than water, carrying heavy items and the likelihood of contaminants being present on the floor and perception of those contaminants, will shift the risk profile.

Table 5 assists to categorise the consequences of slipping in perspective of other adverse occupational health effects as contextualised by Firth et al (2006). Evaluating the qualitative measure of consequences should a person fall on the level or on stairs, musculo-skeletal injury is the most probable outcome, being considered level 3 – moderate.

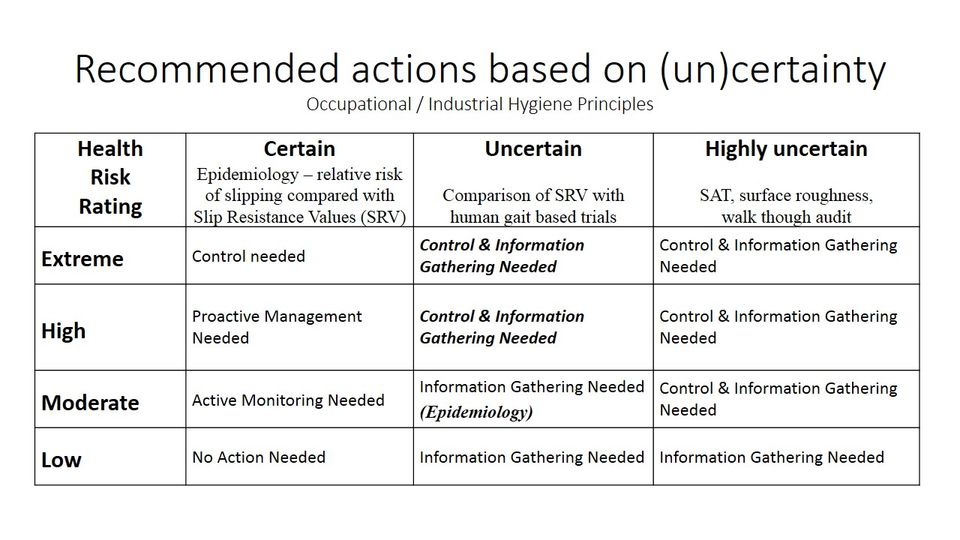

A Health Risk Rating (Table 6) is calculated in context of the likelihood and consequences which provides recommended actions based on the uncertainty (Table 7). The degree of (un)certainty may comprise: walkthrough audits by personnel experienced in slip resistance testing (i.e. Bayesian statistics) or the use of surface roughness measurements (Health & Safety Executive, Slip Assessment Tool) as being highly uncertain; the comparison of SRVs that relate to the risk of slipping under certain conditions, such as the set of ASTM reference samples (uncertain); or certain, whereby validated statistical SRVs are incorporated within epidemiological studies to assess the SRV where a disproportionate number slips may be expected to occur compared with the background population (relative risk), which takes into consideration potential confounding factors such as perception of slipperiness.

Where control is required it is recommended to substitute or modify the floor to increase the SRV. Samples of alternative surfaces or identified treatments should be evaluated in terms of the increase in slip resistance and any other characteristic deemed to be important which may include; cost, cleanability, mechanical properties, chemical properties adhesion to surface and aesthetics. Ideally a trial of suitable options over time will provide adequate information to conduct a cost-benefit analysis of the long term sustainable slip resistance.

Proactive management of slip related injuries includes active monitoring in conjunction with a combination of soft control measures such as: isolation (limit access to high-risk areas i.e. restricting access while cleaning is in progress), engineering methods (reduce water traipsed in during wet weather through water absorbent matting, apply floor treatments such as acid etching and proprietary products on a regular basis, improve lighting etc.), administrative controls (wet weather procedures, provision of umbrella wrapping machines, good housekeeping and adequate cleaning regimes) and personal protective equipment (slip resistant footwear).

Table 4. Qualitative Measures of Likelihood

| Descriptor | Risk Context | HB 197 Context | Suggested Occupational Hygiene Context |

|---|---|---|---|

| Almost certain | Is expected to occur in most circumstances |

Extremely slippery; Safe for short stride and extreme care; Slip highly probable without extreme caution |

Less than SRV where all slips occur at normal walking pace (1.3 m/s). Possibly < 15 Slider 55 & 96 |

| Likely | Will probably occur in most circumstances. |

Noticeably slippery; Safe for reduced stride and cautious pace; Non-slip with caution |

Between SRV where all slips occur and SRV where no heel slips occur at normal walking pace (1.3 m/s). Possibly between 15 & 25 Slider 55 & 96; |

| Possible | Might occur at some time. |

Detectably slippery; Safe for normal stride, pace and attention; Non-slip with reasonable care “reasonably safe” |

Between SRV where no heel slips occur and SRV where no toe slips occur at normal walking pace (1.3 m/s). Possibly between 25 & 30 Slider 55 & 96 |

| Unlikely | Could occur at some time. |

Non-slip; Safe for normal stride and pace and moderate attention; Non slip at involuntary pace |

Between SRV where no toe slips occur at normal walking pace (1.3 m/s) and SRV where no heel slips occur at hurried pace (2.1 m/s). Possibly between 30 & 45 Slider 55 & 96 |

| Rare | May occur only in exceptional circumstances. |

Detectably less slippery; Safe for hurried stride and pace and minimal attention; Non-slip at rapid pace |

Greater than SRV where no heel slips occur at hurried pace (2.1 m/s). Possibly > 45 Slider 55 & 96 |

Table 5. Qualitative Measures of Consequences

| Descriptor | Risk Context | Occupational Hygiene Context | Description of Health Effects |

|---|---|---|---|

| Insignificant | No injuries | Can cause reversible health effects of little concern, requiring first aid treatment at most | Minor irritation of eyes, nose, throat and/or skin; Minor muscular discomfort Headaches |

| Minor | First aid treatment | Can cause reversible health effects that result in medical treatment with no lost time |

Narcosis; Moderate irritation of eyes nose, throat and/or skin; Sea sickness, sunburn, heat rash |

| Moderate | Medical treatment required | Can cause severe, reversible health effects of concern – could result in a lost time illness | Musculo-skeletal injury; Short term physical effects (sunstroke, frostbite) Nervous system effects other than narcosis; Non-fatal airborne disease. |

| Major | Extensive injuries | Can cause a single fatality or irreversible health effects or disabling illness to one or more persons | Progressive chronic conditions such as hearing loss, pneumoconiosis, chronic obstructive pulmonary disease, Systemic poisons |

| Catastrophic | Death | Can cause multiple fatalities or significant irreversible effects | Carcinogens; Reproductive toxins, Asphyxiants, Life threatening responses. |

Table 6. Health Risk Rating

| Likelihood | 1 Insignificant | 2 Minor | 3 Moderate | 4 Major | 5 Catastrophic |

|---|---|---|---|---|---|

| A | Moderate | High | Extreme | Extreme | Extreme |

| B | Moderate | Moderate | High | Extreme | Extreme |

| C | Low | Moderate | High | Extreme | Extreme |

| D | Low | Low | Moderate | High | Extreme |

| E | Low | Low | Moderate | High | Extreme |

Active monitoring requires comparing SRVs with incidence of falls to assess where there may be a disproportionate number of falls occurring to that of the background number of falls; and auditing controls and/or proactive management strategies in place, ensuring they are effective (such as use of water absorbent matting to reduce water being traipsed into designated dry floor areas). The results of active monitoring will assist in providing further epidemiological evidence to assess confounding factors and establish stronger relationships of the incidence of slips resulting in falls with corresponding SRV’s.

Table 7. Recommended actions based on (un)certainty

| Health Risk Rating | Certain | Uncertain | Highly uncertain |

|---|---|---|---|

| Extreme | Control needed |

Control & Information Gathering Needed |

Control & Information Gathering Needed |

| High | Proactive Management Needed |

Control & Information Gathering Needed |

Control & Information Gathering Needed |

| Moderate | Active Monitoring Needed | Information Gathering Needed |

Control & Information Gathering Needed |

| Low | No Action Needed | Information Gathering Needed | Information Gathering Needed |

Summary

The results of inter-laboratory testing for the four ASTM F2508 reference samples to AS/NZS 4586:2004 Appendix A wet pendulum slip testing correctly ranked the surfaces for slider 55; however there was insufficient statistical significance for slider 96 at the 95th percentile between RS A & RS B. Inter-laboratory variability may be reduced through refining calibration methods such that individual tribometers conform to ASTM 2508 and/or the use of normalising results to known reference samples.

The critical points in the human gait based system are discussed to integrate within a risk management model. This risk management model provides an initial framework for organisations to prioritise the risk of slip and fall injuries comparably with a range of adverse health effects afforded through ergonomic, chemical, physical, biological and psychosocial stressors. Epidemiological studies are required to refine and validate the gait-based risk model to allow for confounding factors in a variety of settings.

References

- ASTM International. Standard Practice of Validation and Calibration of Walkway Tribometers Using Reference Standards (No. ASTM F2508-11). West Conshohocken, PA

- Finnis, K.K, & Walton D., (2008) Field observations to determine the influence of population size, location and individual factors on pedestrian walking speeds, Ergonomics, 51:6, 827-842.

- Firth, I, van Zanten, D, Tiernan, G (2006). Simplified Occupational Hygiene Risk Management Strategies. Tullamarine: Australian Institute of Occupational Hygienists Inc.

- Hunter, R, Jablonsky, R, Mercher, J (1985), Development of coefficient of friction measurement methods by consensus –standards-making organizations, Ergonomics 28:7, 1055-1063

- Powers C, Blanchette, M, Brault, J, Flynn, J, Siegmund, G (2010) Validation of walkway tribometers establishing a reference standard, Journal of Forensic Science, 55:2, 366-370

- Redfern, M.S., Cham, R., Gielo-Perczak, K., Gronqvist, R., Hirvonen, M., Lanshammar, H., Marpet, M., Pai, -Y.C., Powers, C (2001) Biomechanics of slips, Ergonomics, 44:13, 1138-1166.

- Standards Australia (1999). An Introductory guide to the slip resistance of pedestrian surface materials (HB 197). Sydney, NSW: Standards Australia.

- Standards Australia (2004). Slip resistance classification of new pedestrian surface materials (AS/NZS 4586:2004). Sydney, NSW: Standards Australia

- Strautins, Carl J (2007) ‘Enhanced Test Method for Assessing Sustainable Slip Resistance’, International Ergonomics Society Conference on Slips, Trips & Falls 2007 : From Research to Practice, Boston USA.

Be absolutely assured. Safe Environments is NATA accredited for Noise testing

Ensure a Safe Environment

For more information on noise testing or management please contact one of Safe Environments Occupational Hygienists or Noise Consultants located in the following Australian cities:

Melbourne & Victoria

Unit 25, 1 Millers Rd Brooklyn VIC 3012 Australia

NSW - Sydney, Newcastle & Wollongong

Unit 4, 40 Bessemer Street, Blacktown NSW 2148