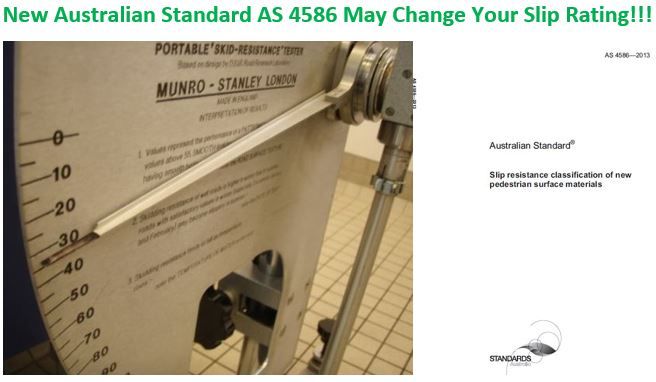

The 2013 versions of AS4586 Slip Resistance Classification of New Pedestrian Surface Materials have brought in a few changes that can seem confusing at first, but are in reality not all that different to the previous versions of the slip testing standards.

What has changed in the new Australian Standard for slip testing?

The main things that have changed are the preparation of the rubber slider, the way the path length is measured and what appears to be the most confusing is the new classification system.

Changes in the preparation of slider

The rubber slider has an extra step in its preparation before testing the surface commences, and that is the introduction of lapping film. After conditioning with P400 sandpaper the rubber slider is conditioned further with ten swings on the lapping film, producing a contact patch on the rubber that is smoother.

Changes in the path length

The path length that the rubber slider is in contact with the surface during the slip test is measured slightly differently. Instead of measuring from the rubber connecting with the surface, which at times was difficult to define exactly where to measure, the rear of the metal backing plate is now used as the reference point. This gives a more defined position to measure from that does not change as the rubber is conditioned, resulting in a more consistence and accurate path length.

Changes to the slip resistance classification system

The part of the new Australian standard that creates the most confusion is the introduction of a new slip rating system, P0 through to P5. The main difference between this and the old 2004 Australian standard is just the name of the classification, and one extra classification has been added to differentiate between results in the old ‘Z’ classification. The changes are outlined below in the table to show the new 2013 changes in AS 4586:.

|

2004 Standard Classification |

BPN Range |

2013 Standard Classification |

|

V |

> 54 |

P5 |

|

W |

45 → 54 |

P4 |

|

X |

35 → 44 |

P3 |

|

Y |

25 → 34 |

P2 |

|

Z |

12 → 24 |

P1 |

|

< 12 |

P0 |

How does this affect the floor slip test results?

The changes in preparation of the rubber slider can tend to give differing results if the surface being tested is very smooth or very rough, however these are not usually very significant. However it should be noted that in some instances, there can be significant changes. Much of these changes observed tend to be on smoother materials that may rely on porosity and/or a small amount of roughness of the surface more. These surfaces tend to be those such as honed stone and acid etching treatments. It is recommended that all surface be tested to the new standard to assess how the changes in the Australian Standards may have changed the reported result. It may be that slip testing to the new standard may highlight a potentially hazardous surface that requires remediation thereby reducing possible injury.

For slip resistance testing to the new 2013 Australian Standard and assess the potential change to your product or installed surface, please contact the Slip Check team at Safe Environments in Sydney or Melbourne.

Author: Ryan Voorderhake

Email: info@SafeEnvironments.com.au

Ryan Voorderhake is a tertiary qualified slip resistance testing consultant with Safe Environments having a completed a Bachelor of Forensic Science (Honours) in Applied Chemistry at the University of Technology, Sydney. Ryan is proficient having undergone successful completion of Safe Environments NATA endorsed training program in wet pendulum testing, dry floor friction testing, oil wet ramp testing and pendulum calibrations to the Australian Standards AS 4586 & AS 4663. With a size 13 boot, Ryan is the giant of floor slip testing when undertaking the oil wet ramp test.

Ryan is proficient in conducting luminance reflectance testing to determine compliance with luminance contrast testing. Luminance contrast testing is a useful aid to assist visually impaired persons in wayfinding.

As well as a qualified floor slip tester, Ryan utilises his forensics degree in conducting asbestos analysis and materials testing duties for ceramic and stone tiling systems.