Sustainable Slip Resistance: An Opportunity For Innovation

by Carl Strautins

Abstract

Ceramic tiles along with most flooring surfaces can become less slip resistant with use. This can occur rapidly such that some relatively new products can become hazardous within a short period of time. Currently there are no recognised methods to identify such problematic products. This introductory paper highlights the benefit of using accelerated wear test methods in combination with portable tribometers to evaluate long term slip resistance. These methods provide manufacturers an opportunity for innovation by identifying and satisfying consumers’ expectations for sustainable slip resistant tiles. Product development occurs effectively through a systematic process of continual improvement. Manufacturers that develop suitable products will create a superior position in this growing niche market.

Introduction

Based on the current state of building construction and regulation, the main health and safety risks in buildings appear to be from slips trips and falls (Atech Group, 2003). While building regulations have reduced most societal risk, individual risks have been gaining prominence, particularly in developed countries where the cost of slip and fall public liability claims is high. European Union Directive 85/374/EEC, which applies to construction products, seeks to protect the physical well-being and property of the consumer. Defectiveness of the product is determined by reference not to its fitness for

use, but to the lack of the safety which the public at large is entitled to expect.

Many building codes have safety performance requirements; not only for slip resistive surfaces, but also that they must continue to perform at the level they were originally required to achieve. This is emphasised by European Union Directive 89/106/EEC, such that tiles must be fit for their intended use over their working life to ensure the safety of occupants throughout the life cycle of a building. This is highlighted as a basic safety requirement of the Spanish Technical Building Code (Navarro 2006). “The

objective of the basic requirement ‘Safety in use’ (SU) consists of reducing to acceptable

limits the risk of users suffering immediate injury during the intended use of the

buildings, as a result of their design, construction and maintenance characteristics”

(Navarro et al 2006).

Safe design employs life cycle concepts and applies to every phase from conception through to disposal. As well as slip resistant flooring, risk minimisation strategies must take a holistic approach incorporating design features (awnings, airlocks and matting) to reduce the extent and likelihood of contamination, visual aids (warning signage and contrasting stair nosings), administrative controls (cleaning regimes and maintenance), fall prevention aids (barricades and handrails), environmental conditions (lighting and sloping surfaces) and specialised footwear.

Conscientious architects understand the need to specify floor surfaces in terms of slip resistance, obtain test results, and document that they have mitigated the risk of pedestrian slip incidents. Ideally the slip resistance of surfaces would not change; however, slip resistance audits have long confirmed that the performance of many seemingly slip resistant materials will reduce significantly over time. Thus test results obtained on factory fresh surfaces may be illusory, misleading designers into specifying products that may be potentially hazardous within weeks or months of installation.

This has serious implications for the architect when specifying a surface. The loss of slip resistance with use may be attributed to a range of complex interacting factors including the installation process, surface treatments, maintenance and wear. Slip resistance will always be part of a wider set of design objectives including practicality, aesthetics, cleanability, cost and functionality. These sometimes competing objectives need to be balanced in a manner that does not compromise the safety and health of those who access the building.

Currently there are no recognised accelerated wear test methods to assess or predict sustainable aspects of pedestrian slip resistance. Silva et al (2006) have proposed an enhanced method for assessing the durability of flooring exposed to pedestrian traffic, but the abraded area is too small for subsequent pendulum testing. Appropriate accelerated wear tests would enable organisations that design, construct and procure their own assets, to minimise their exposure to risk in slip and fall incidents and litigation.

One form of innovation is identifying what is incongruous between the reality ‘that is’ and the reality ‘that should be’ (Martin 2006). The reality is that slip resistance can deteriorate significantly over a short time; consumers assume that tiles will maintain sufficient slip resistance over time, if not the original amount. Highlighting the deficiencies in competitors’ products (reality that is) whilst developing sustainable slip resistance tiles (reality that should be), provides a means for ceramic tile manufacturers to differentiate their products against their competitors, whilst satisfying the end users needs: thus providing an opportunity for innovation. This could be a winning competitive strategy in mature markets of developed countries such as the US. However, Bowman et al (ASTM STP 1424) question the accuracy of the American slip resistance test methods, highlighting the need for an ISO standard.

Development Of An Accelerated Wear Test Method

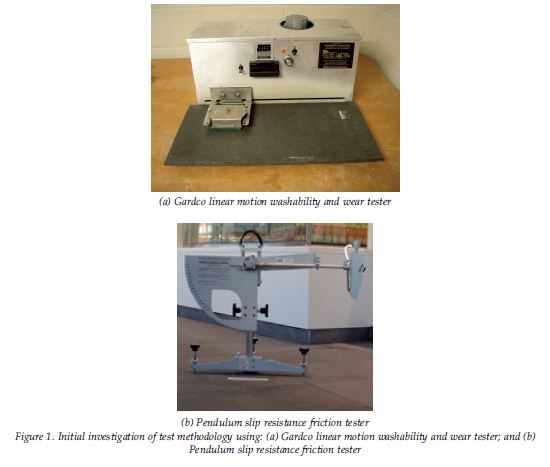

A Gardco 12VFI linear motion washability and wear tester was used to develop an accelerated wear test. This apparatus has traditionally been used to assess the wear resistance of paint systems using nylon bristle brushes. The machine has a 100mm x 100mm friction boat, which is cradled within a fork drive. Different abrasive materials were fixed to the bottom of the friction boat, which was set to operate at a rate of 50 cycles per minute, traversing backwards and forwards over a 300 mm path length. The pressure on the (water) wetted test specimen was controlled by adjusting the friction boat weight.

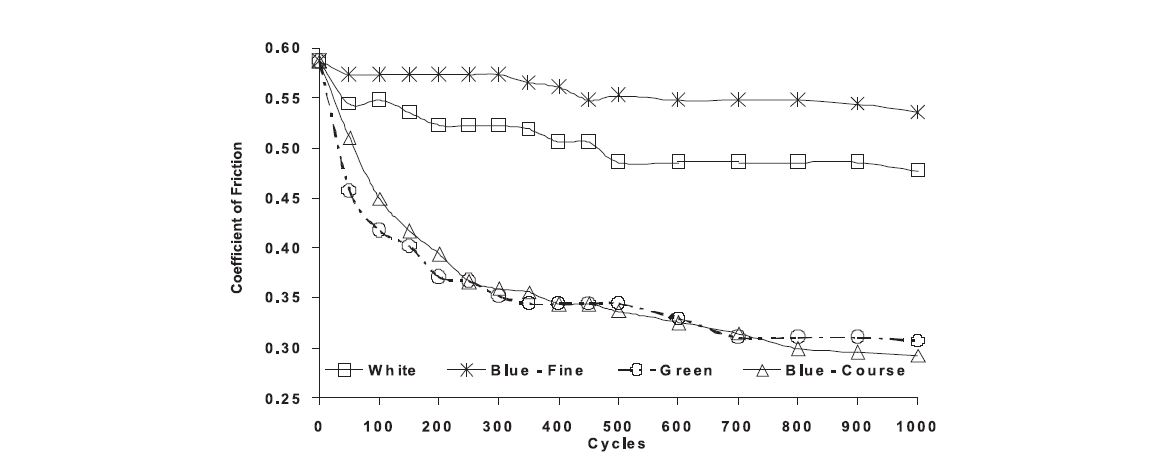

Initially the effect of the abrasive material and the applied pressure was investigated using a dust pressed, glazed ceramic tile. Four grades of 3M nylon cleaning pads were used for the study. They are identified by colour, in order of ascending abrasiveness: White – Light Duty No.98, Blue Fine -Power Pad No.2000,

Green – Heavy Duty No.86, Dark Blue – Extra Heavy Duty No.88. These abrasive pads were used in combination with three weights of 500 g, 1000 g and 2000 g. A batch of 40 ceramic tiles were tested to AS/NZS 4586 using the wet pendulum with Four S (Slider 96) rubber material conditioned with P400 Grade abrasive paper, allowing tiles which measured a dynamic coefficient of friction (DCOF) of 0.59 to be selected for accelerated wear testing. The DCOF was re-measured after every 50 wear cycles to a total of 1000 cycles.

Further accelerated wear and wet pendulum testing was conducted, introducing a second ceramic tile. Both tiles had been used in the customer service area of several high traffic volume restaurants. From user opinion surveys, tile 1 was considered to maintain an acceptable level of slip resistance (it typically achieved a DCOF of 0.35 after 1 year when measured in situ), whilst tile 2 was thought to become hazardous after a short period of time, (DCOF of 0.20 after 1 year).

New specimens of these ceramic tiles were subjected to 100, 500, 1000 and 5000 cycles of accelerated wear using a Green 3M Scotch Brite abrasive pad with a total weight of 1000 g to determine the effect of pressure during abrasion.

2.1. Results

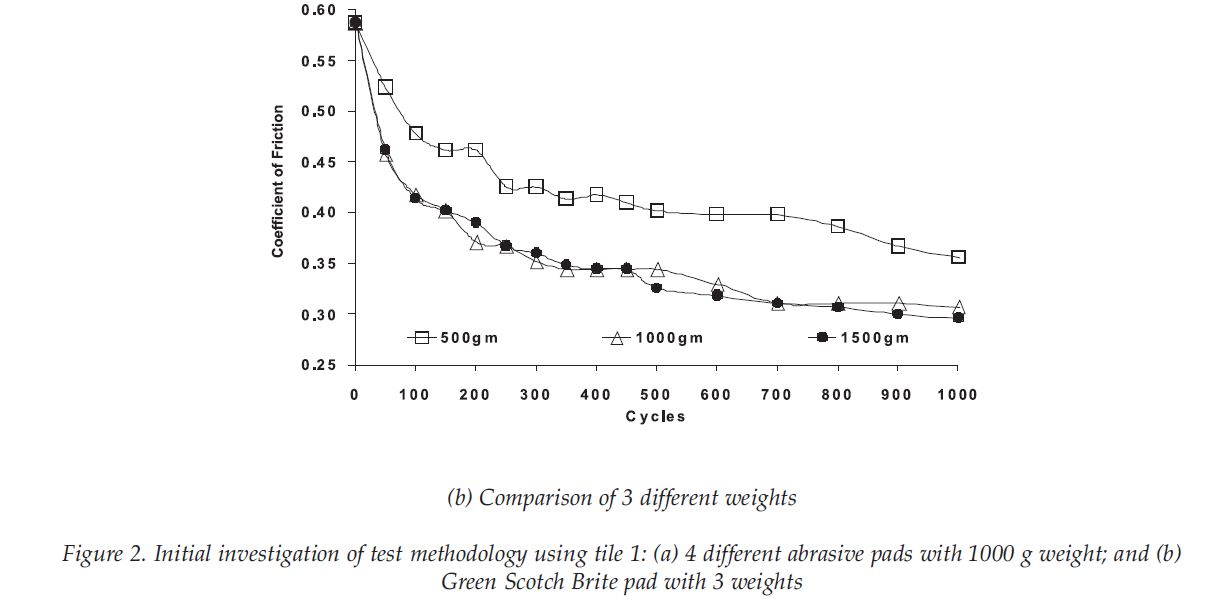

The results are shown graphically in Figure 2. Figure 2(a) depicts the relative difference between the 4 abrasive pads. While the white and fine blue abrasive pads resulted in slight ongoing changes in slip resistance, there was a more pronounced change with the coarse green and blue abrasive pads. The green pad was then used to evaluate the effect of applied pressure (500 g, 1000 g and 1500 g weights) as depicted in Figure 2 (b). No significant difference was observed between the 1000 g and 1500 g weights. The green pad was easier to mount to the friction boat than the coarser blue pad. The green 3M Scotch-Brite abrasive pad was thus selected with a 1000 g weight for accelerated wear use in an extensive range of further sustainable slip resistance studies.

Be absolutely assured. Safe Environments is NATA accredited for Noise testing

Ensure a Safe Environment

For more information on noise testing or management please contact one of Safe Environments Occupational Hygienists or Noise Consultants located in the following Australian cities:

Melbourne & Victoria

Unit 25, 1 Millers Rd Brooklyn VIC 3012 Australia

NSW - Sydney, Newcastle & Wollongong

Unit 4, 40 Bessemer Street, Blacktown NSW 2148